Industries & Applications

Soluble core and sacrificial tooling with 3D printing

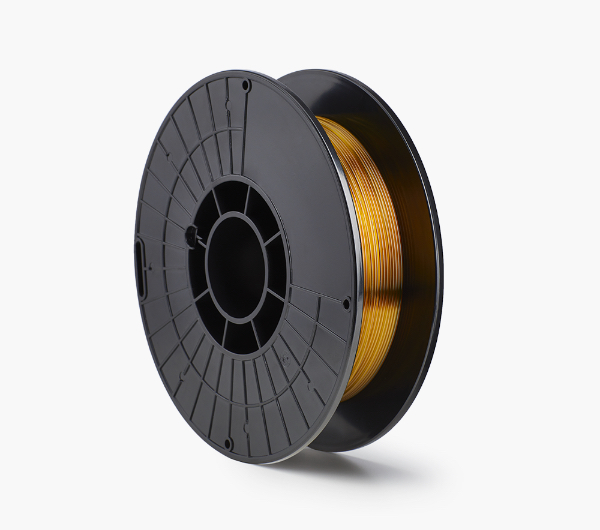

AquaSys® 180 offers superior compatibility and outstanding material characteristics for soluble core applications.

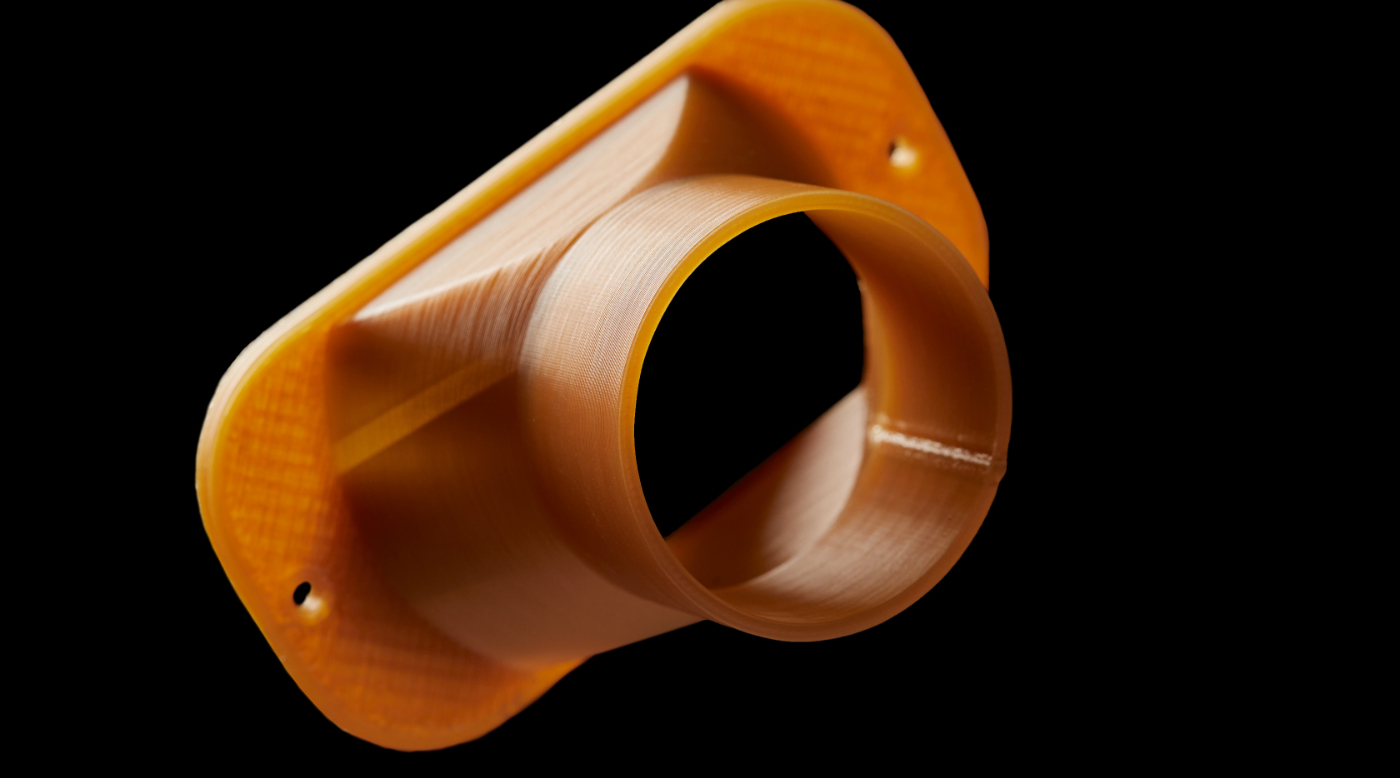

Create complex forms.

Create complex forms.

Create soluble core hollow forms with complex geometry and overhangs. Open up new options for composite production forms.

Realize faster time-to-part.

Realize faster time-to-part.

Produce tools using additive manufacturing in days — not months. Work even faster thanks to AquaSys® 180’s fast water-only dissolution.

Design for performance.

Design for performance.

AquaSys 180 is compatible with a wide range of materials requiring higher temperatures, like PEEK, PEKK, PEI, and PPSU.

Keep it clean.

Keep it clean.

Superior material adhesion means no wrinkles and smoother interior surfaces for carbon composite forms.

Soluble core solutions.

Infinite™ materials enable complex designs, expanded material compatibility, and a reduced time-to-part rate for users seeking the design freedom and flexibility of open printing systems. Learn how our support and build products can help solve your end-part design challenges.

Support Materials