Industries & Applications

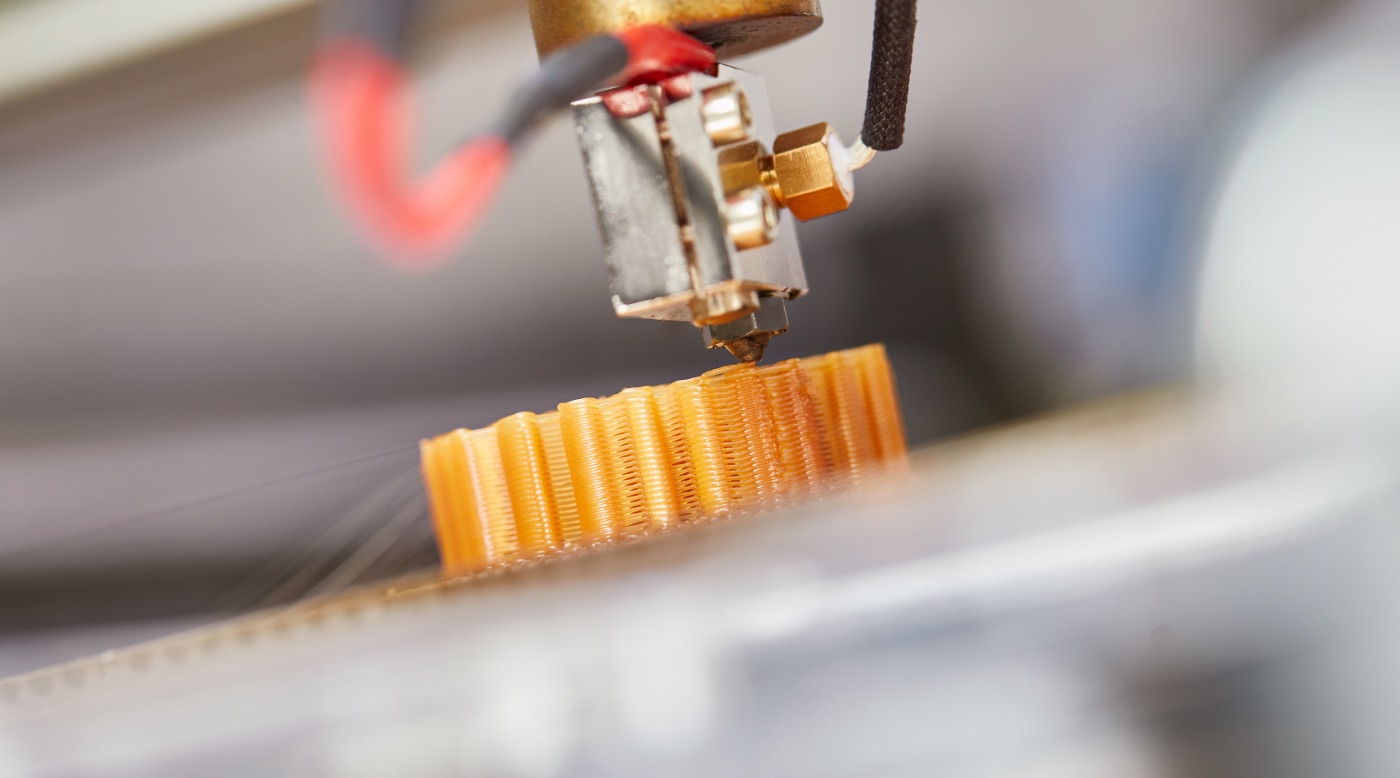

3D printed jigs and fixtures: getting the job done, better

Jig and fixture production is the heart of 3D printing in manufacturing, driving efficiency, accuracy, and safety gains.

Improved time to part.

Improved time to part.

Broader applications.

Broader applications.

Increased accuracy.

Increased accuracy.

Materially better.

Materially better.

Solutions for jigs, fixtures, and production tooling.

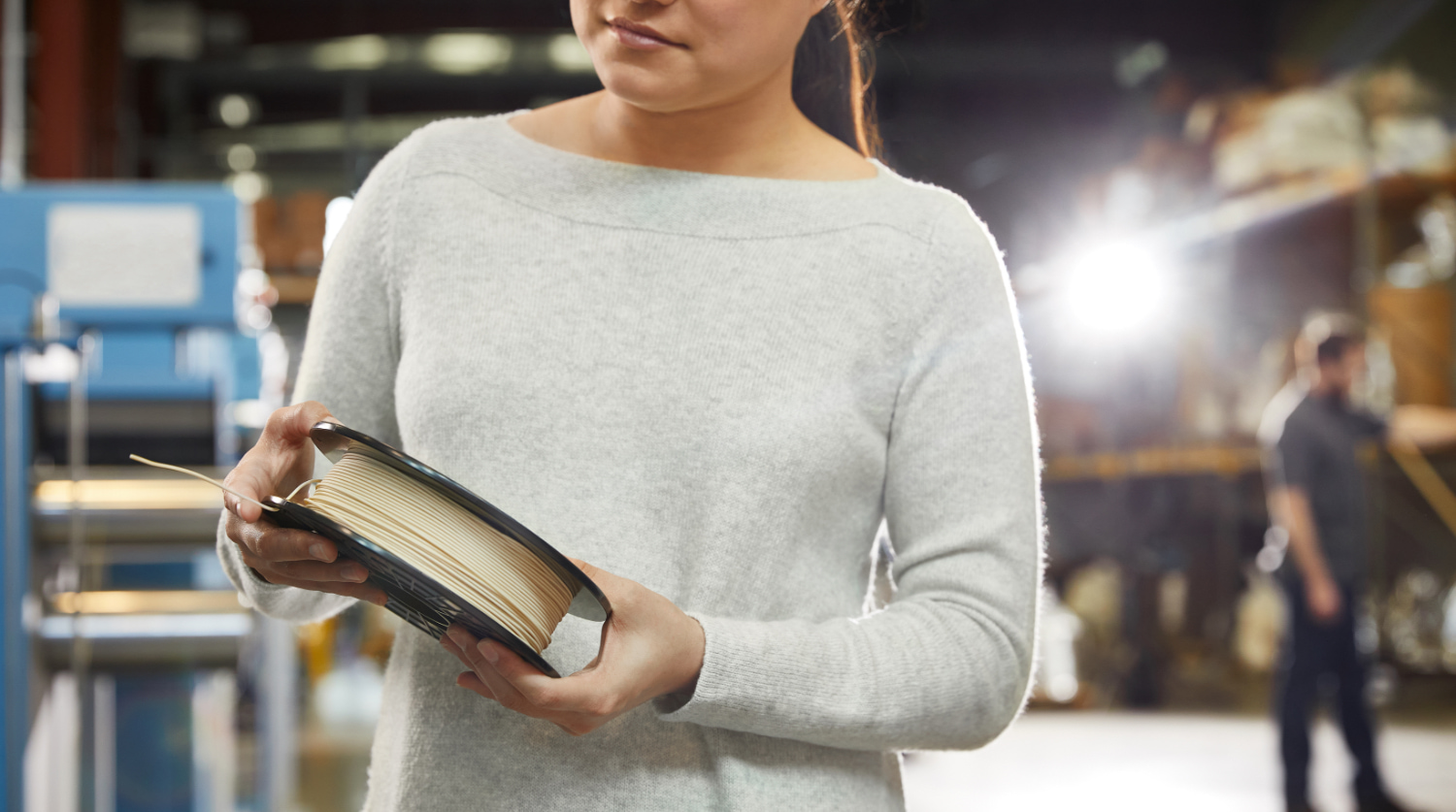

Ready to put your own 3D printed jig to work? Infinite materials enable complex designs, expanded material compatibility, and a reduced time-to-part rate for users seeking the design freedom and flexibility of open printing systems. Learn how our support and build products can help solve your manufacturing challenges.

Support Materials

Our AquaSys water-only soluble support filaments offer high-quality support, ease of use, and unmatched compatibility.

Build Materials

Caverna, our unique new build material, can be used in thermoforming applications where a porous tool is specified. Caverna's continuous morphology eliminates the need to drill vent holes and improves part quality thanks to an evenly distributed vacuum draw.