News & Resources.

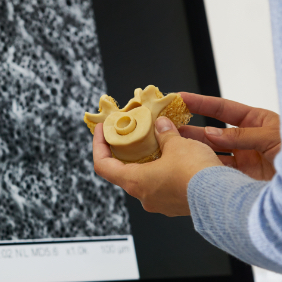

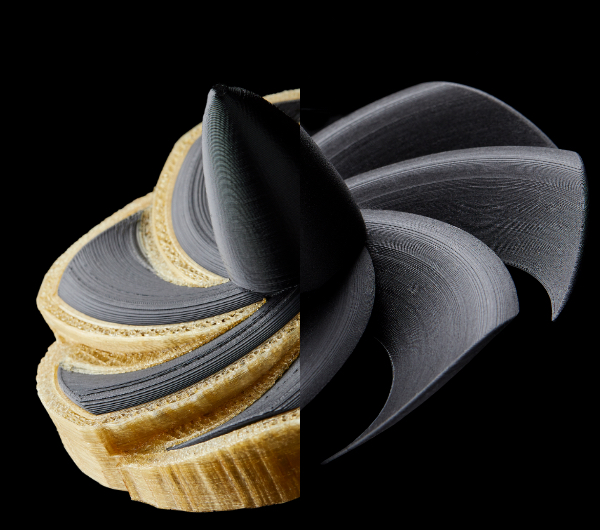

The critical role of supports.

Print the future.

Whether your fused filament fabrication task calls for porous build structures, water-soluble supports, or support filaments that pair with high-temperature build materials, our products solve previously unsolvable problems for a wide range of industries.

Aerospace.

Superior thermal stability and best-in-class adhesion characteristics remove design constraints and enable more efficient production.

Automotive.

Improve your time-to-part prototyping and enjoy expanded material compatibility with materials fully compatible with open additive manufacturing systems.