Understanding microporous morphology

The hole story of 3D-printed foam

Additive manufacturing has long sought a solution to two of the biggest restrictions often faced with traditional materials: rigidity and heaviness. Today, 3D-printed foam and microporous morphology solve for both.

What isn’t there is what makes it great

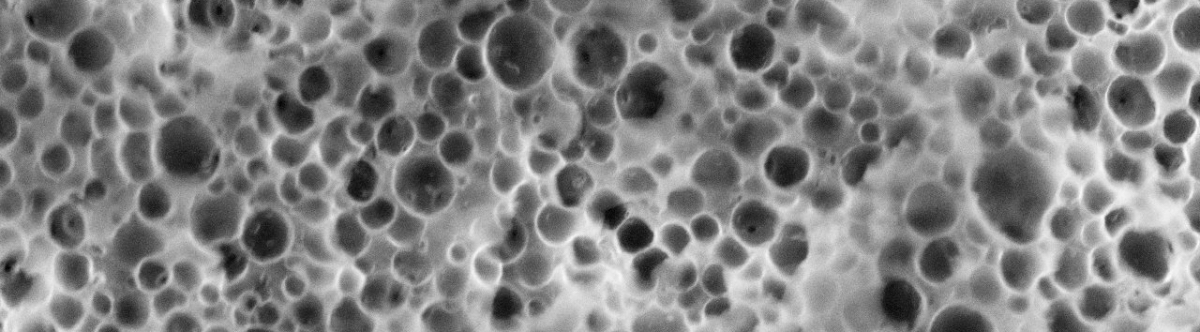

3D-printed foam is achieved when you print a structure that has breathable pores. It can be firm or pliable, and water-soluble or not, all of which solve common problems faced in 3D printing. In the context of additive manufacturing, microporous morphology is achieved when you print a structure with extremely small pores. For example, Infinite™ Material Solution's Caverna™ PP material has a pore size of 1-4µm (microns).

From the factory floor to the operating room and beyond

3D-printed foam works better than standard cellular materials in terms of durability and long-term mechanical performance, making it an ideal resource in a variety of industries, including transportation, medicine, and aeronautics.

Moving technology forward

From armrests and tray tables to hand breaks and air filters, many interior parts in autos, plane cabins, and train cars require soft, lightweight, and spongy materials.

In 2019, all of the Formula 1 constructor teams used additive manufacturing to print parts for their race cars. While those parts weren’t porous, the ability to print foam-like parts that can withstand heat and form complex geometries opens up even more potential for 3D printing in the sport. One such promising application: air filters that can be printed to the specification of the tight and awkward spaces within and around the driver’s cockpit.

3D-printed foam is incredibly well suited for off-the-ground uses as well. In an industry where every ounce must be accounted for, the relatively lower weight of 3D-printed foam makes it a material of great interest to those in aeronautics.

In a test on a remote-control plane comparing the performance of three different wing materials — traditional foam, 3D-printed PLA, and 3D-printed foam made from colorFABB’s LW-PLA (lightweight polylactic acid) — the latter performed as well as a traditional wing and better than the PLA wing. As 3D printing becomes more adopted and commonplace in all industries, the speed to prototype and create lighter end products will be of great use in aeronautics.

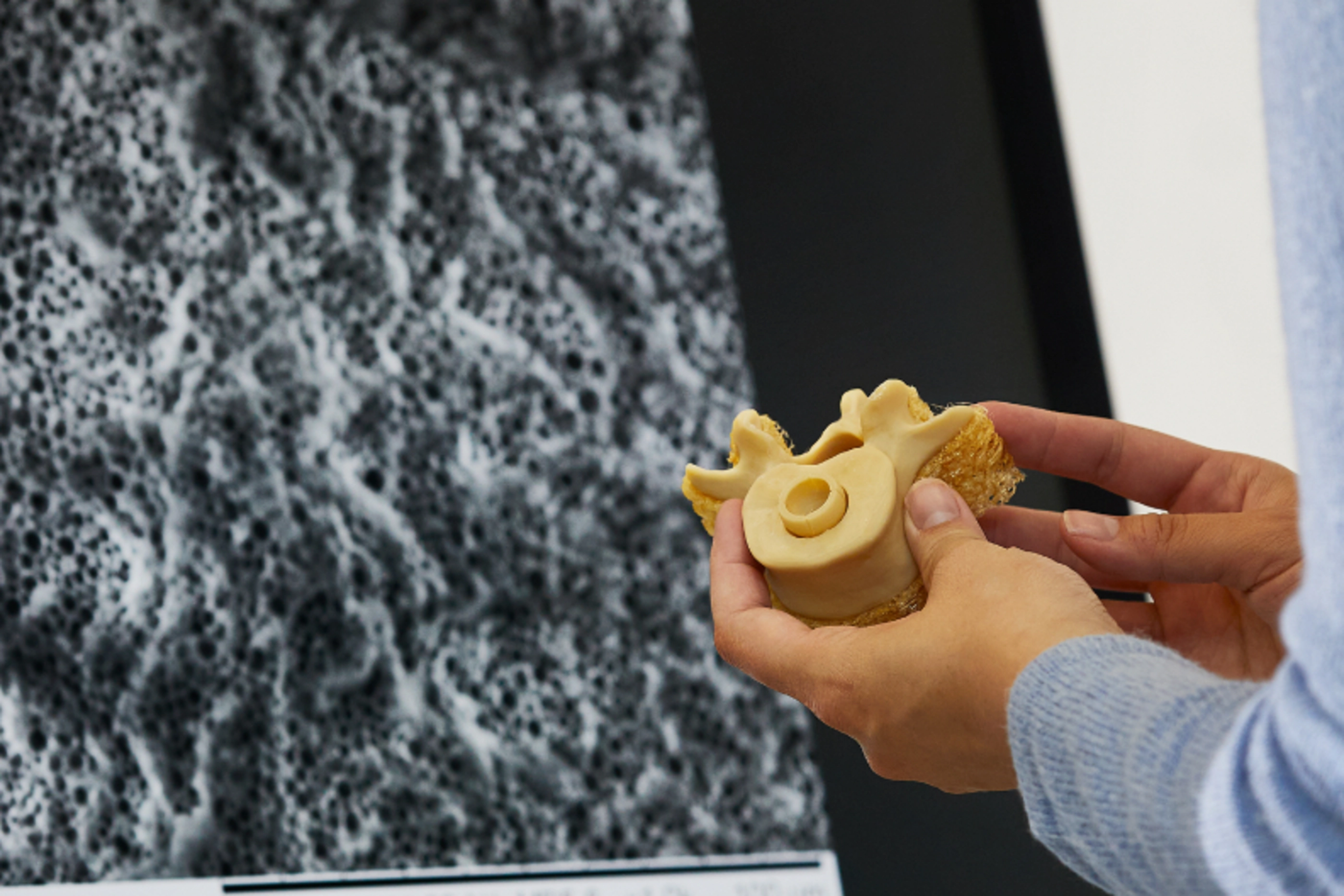

Advancing medicine, one pore at a time

Developments in manufactured porous materials make it a go-to in the medical industry. Its resemblance to bones, breathability, and varying density offer great advantages in medical research and hospitals. In a field where time is often of the essence, 3D printing can put these materials into the hands of doctors and scientists quicker than ever.

In 2020, COVID-19 wreaked havoc on supply chains, creating medical supply shortages. In response, a team at the University of Louisville designed a unique solution: a novel 3D-printed swab made of a pliable resin material.

3D printing also allows for the creation of realistic models, enabling researchers to study new devices in clinical situations and establish their effectiveness before they are introduced to patients. The technology is also being used for orthotics and prosthetics.

Space: A frontier made for 3D-printed foam

Since 2014, the International Space Station has had a 3D printer onboard. When a new or replacement part is necessary, printing it is far easier than waiting for it to arrive from Earth. Because square footage and time onboard ships and space stations are at a premium, the ability to create parts on-demand instead of bringing them along makes 3D printing a vital part of space exploration. And because many of those parts need to be strong, lightweight, breathable, or insulating, 3D-printed foam with microporous morphology is an ideal fit.

When French astronaut Thomas Pesquet flew to the International Space Station, he brought with him 3D-printed parts, including packaging for meals. These parts were designed from a recyclable, edible foam made from PHA, a naturally occurring polymer. Capabilities like these hold great interest as the space exploration industry looks forward to a longer, more distant time in space.

Running to the future

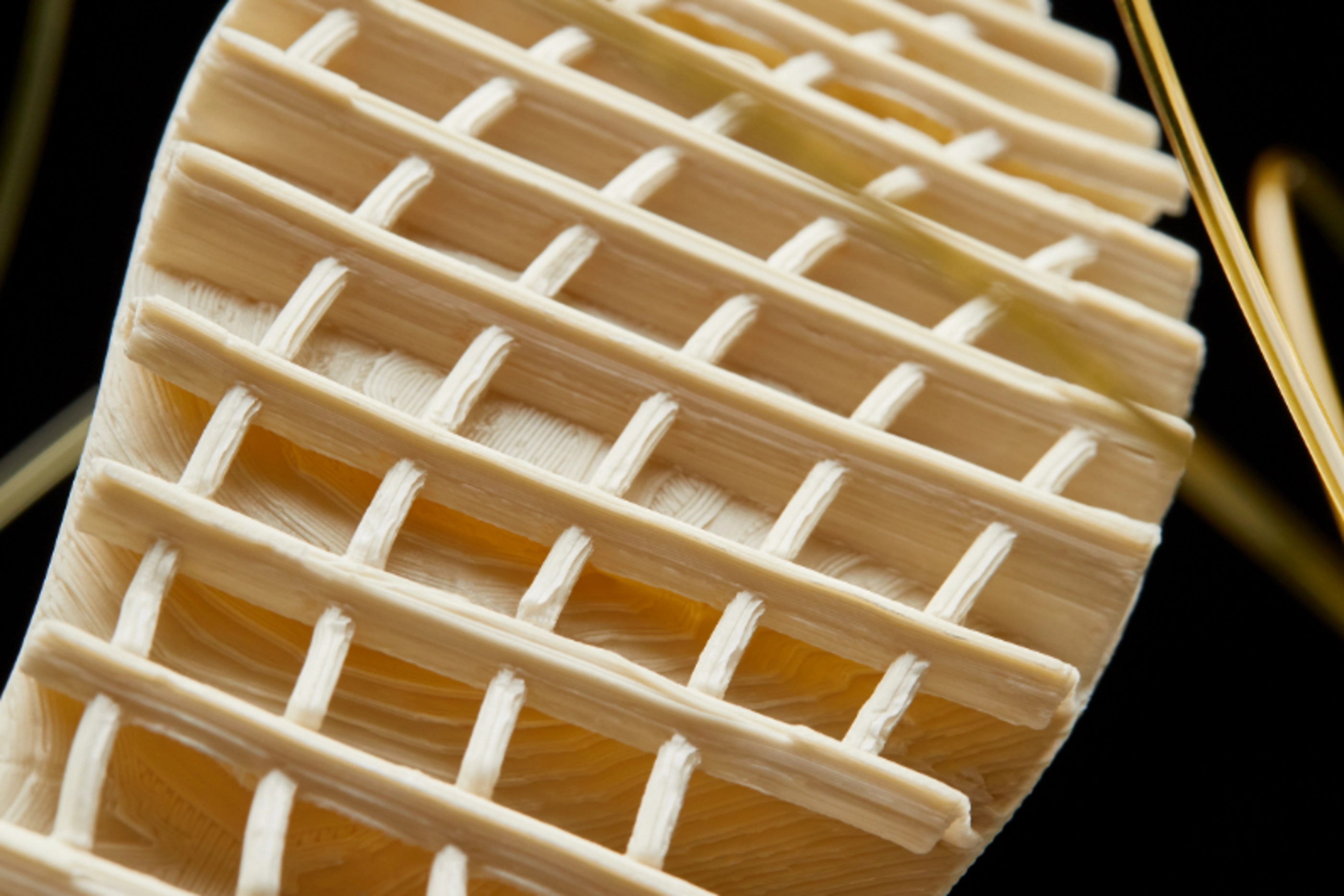

Most athletic gear needs to be breathable, pliable, and water-resistant. With 3D printing, sportswear manufacturers can achieve these qualities in their products, including various parts of sneakers. Insoles need to offer support while also providing the right amount of responsiveness for a runner’s movements. In the future, 3D printing can allow for individual customization of shoes at a speed and accessibility not seen before.

In collaboration with 3D printing specialist Materialise, Adidas is working on a shoe designed to the specifications of an individual runner’s footprints. According to Eric Liedtke of Adidas: “Our 3D-printed mid-sole not only allows us to make great running shoes but also to use performance data to drive truly bespoke experiences, meeting the needs of any athlete.”