Industries & Applications

Build better production parts with additive manufacturing.

Maximize your part performance with best-in-class support materials from Infinite.

Consumer-market ready.

Consumer-market ready.

Look the part. Better adhesion from support materials like AquaSys® means a cleaner part, with fewer steps and less effort in post-production.

In-house applications.

In-house applications.

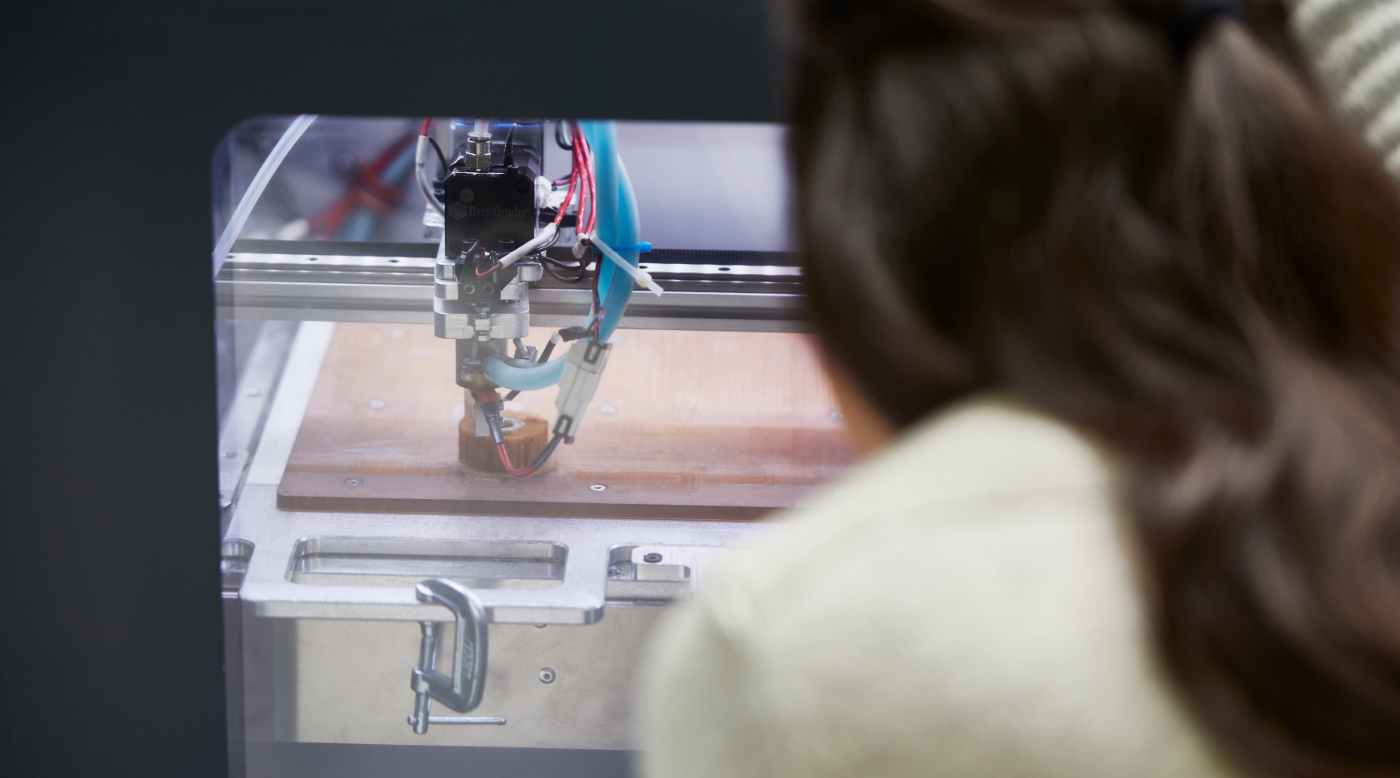

Be nimble, be quick. For lower-volume applications, additive manufacturing can offer striking improvements in cost and time versus other production technologies.

New products, new markets.

New products, new markets.

Additive manufacturing opens up opportunities. AquaSys 180 is compatible with the engineering thermoplastics used for automotive replacement parts.

Rapid production parts.

Rapid production parts.

Leave old technology like CNC and investment casting in the shop-floor dust. Produce tools and guides in hours, not weeks.

Solutions for end-use parts production.

Infinite™ materials enable complex designs, expanded material compatibility, and a reduced time-to-part rate for users seeking the design freedom and flexibility of open printing systems. Learn how our support and build products can help solve your end-part design challenges.

Support Materials

Our AquaSys water-only soluble support filaments offer high-quality support, ease of use, and unmatched compatibility.

Build Materials

Introducing Caverna™ PP, a polypropylene build material with a microporous morphology.