Industries & Applications

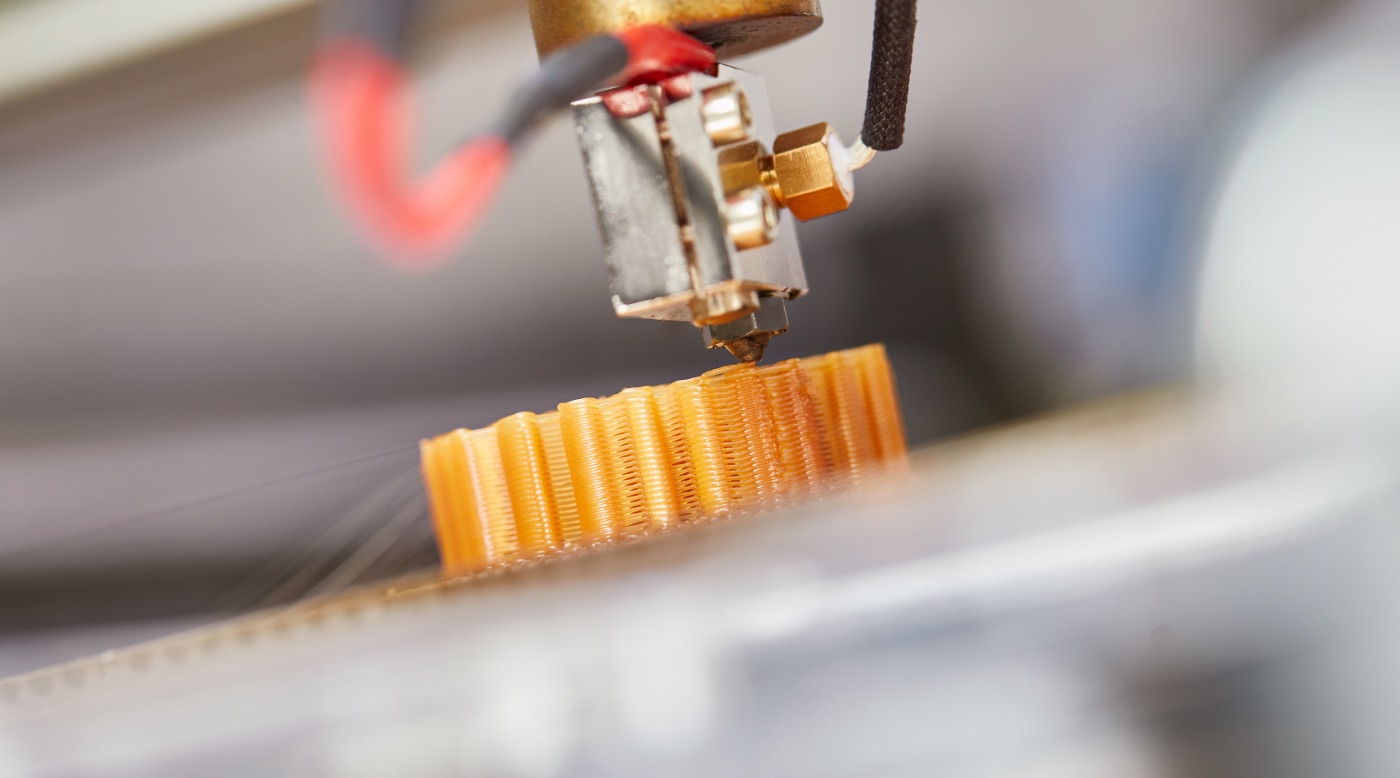

Additive Manufacturing for Automotive

Realize better time-to-part performance using AquaSys® supports and Caverna™ build materials—all fully compatible with open AM systems.

Accelerate prototyping.

Accelerate prototyping.

Save time. AquaSys® offers the broadest compatibility, highest temperature stability, and ease of use of any support material on the market.

Improve jigs & fixtures.

Improve jigs & fixtures.

Create complex features thanks to superior print fidelity and water-soluble support.

Expedite assembly.

Expedite assembly.

Enjoy expanded design freedom. The AquaSys line offers greater AM printing material compatibility.

Accelerate market opportunities.

Accelerate market opportunities.

Work with our industry-first materials to create your industry first in automotive.

Automotive expertise.

Our products for automotive.

Infinite has pushed additive manufacturing forward by enabling more complex designs and an abbreviated time-to-part rate for users seeking the design freedom and flexibility of open printing systems. Learn how AquaSys and Caverna can help solve your automotive design challenges.

Support materials

Our water-only soluble support filaments offer high-quality support, ease of use, and unmatched compatibility.

Build materials

Discover our line of Caverna products, professional-grade build materials that print soft foam-like parts.